Home > Products > Water seal strips > Rubber water-stop construction method (diagram)

Rubber water-stop construction method (diagram)

USD $7.5 - $22.67

/ Meter

1000 Meters(Min.Order)

- 500000 Meter / Meters per Month

- Qingdao

- T/T Credit Card PayPal

You May Like

Product Details

| Place of Origin | Shandong, China | Brand Name | Hongxiang | |

| Model Number | HX-Z-280*6 |

Product Description

Specifications

B type:water stop strip, suitable for easy deformation joint,S type:water stop strip suitable for construction joint

Product Description

Rubber water-stop construction method (diagram)

Rubber water-stop profile sketch

1, the physical properties of rubber water-stop

Design requirements for rubber water-stop must meet the following physical performance indicators: 18 mpa or greater tensile strength, tear strength 35 kn/M, or hardness 60 ° shaw (A) + / - 5 °, breaking elongation is 450% or higher, fixed and permanent deformation of 20% or less, compression permanent deformation of 35%, or less brittle temperature - 45 °C or less, hot air aging (70 °C) x 72 h, hardness change + 8 ° or less, the tensile strength rate (lower) 10% or less, the elongation rate (lower) 20% or less.

2, rubber water-stop joint processing

* * in the project, according to the use of different parts of the same specification rubber water-stop joint as shown in figure 2 (a) ~ (e), there are two specifications rubber water-stop variable cross-section connection, as shown in figure 2 (f) interior wall vertical water-stop lap practice and figure 2 (g) vertical water-stop wall lap. In order to ensure the quality of complex shaped joint such as annular rubber water-stop try to finish in the processing, all kinds of joints were sent to guide field joint by the manufacturer.

1, the physical properties of rubber water-stop

Design requirements for rubber water-stop must meet the following physical performance indicators: 18 mpa or greater tensile strength, tear strength 35 kn/M, or hardness 60 ° shaw (A) + / - 5 °, breaking elongation is 450% or higher, fixed and permanent deformation of 20% or less, compression permanent deformation of 35%, or less brittle temperature - 45 °C or less, hot air aging (70 °C) x 72 h, hardness change + 8 ° or less, the tensile strength rate (lower) 10% or less, the elongation rate (lower) 20% or less.

2, rubber water-stop joint processing

* * in the project, according to the use of different parts of the same specification rubber water-stop joint as shown in figure 2 (a) ~ (e), there are two specifications rubber water-stop variable cross-section connection, as shown in figure 2 (f) interior wall vertical water-stop lap practice and figure 2 (g) vertical water-stop wall lap. In order to ensure the quality of complex shaped joint such as annular rubber water-stop try to finish in the processing, all kinds of joints were sent to guide field joint by the manufacturer.

Rubber hose connector

Field joint using cold joint, the need to connect on both ends of the rubber water-stop cut into mutual matching water-stop rubber joints, joint surface fell after MAO rubber cleaner clean, dry, brush glue stick rubber (double). The sub process is as follows:

(1) in accordance with the requirements for drawing the Angle of the cutting, cutting face to straight, shall not be leant;

(2) cut off strong muscle, in cut off strong muscle place, with electric or pneumatic grinding wheel, MAO MAO parts will comprehensively, must not miss;

(3) after MAO use gasoline or rubber cleaner scrub, after being dry cleaner gasoline or rubber coating mucilage, mucilage coating should be uniform;

(4) according to your drawings after being dry, with 211 rubber paste, first in joining together with the roller compaction and can not have bubbles;

(5) with 211 rubber water-stop rubber bag to stick the joint, after package is stuck with the roller compaction and eliminate air bubbles; (6) inspection appearance raised not obvious bubbles, but allows the film there is a slight uneven surface.

3, rubber water-stop Settings

Rubber water stop pouring concrete in the cross section and into the adjacent concrete and form a embedded in the concrete cross joints or construction joint partition, prevent moisture from one side of the construction joint into the other side. Seam floor rubber water-stop Settings as shown in figure 3 (a) and 3 (b), cracks of rubber water-stop Settings as shown in figure 3 (c), the hole rubber water-stop Settings as shown in figure 3 (d).

Field joint using cold joint, the need to connect on both ends of the rubber water-stop cut into mutual matching water-stop rubber joints, joint surface fell after MAO rubber cleaner clean, dry, brush glue stick rubber (double). The sub process is as follows:

(1) in accordance with the requirements for drawing the Angle of the cutting, cutting face to straight, shall not be leant;

(2) cut off strong muscle, in cut off strong muscle place, with electric or pneumatic grinding wheel, MAO MAO parts will comprehensively, must not miss;

(3) after MAO use gasoline or rubber cleaner scrub, after being dry cleaner gasoline or rubber coating mucilage, mucilage coating should be uniform;

(4) according to your drawings after being dry, with 211 rubber paste, first in joining together with the roller compaction and can not have bubbles;

(5) with 211 rubber water-stop rubber bag to stick the joint, after package is stuck with the roller compaction and eliminate air bubbles; (6) inspection appearance raised not obvious bubbles, but allows the film there is a slight uneven surface.

3, rubber water-stop Settings

Rubber water stop pouring concrete in the cross section and into the adjacent concrete and form a embedded in the concrete cross joints or construction joint partition, prevent moisture from one side of the construction joint into the other side. Seam floor rubber water-stop Settings as shown in figure 3 (a) and 3 (b), cracks of rubber water-stop Settings as shown in figure 3 (c), the hole rubber water-stop Settings as shown in figure 3 (d).

4, rubber water-stop

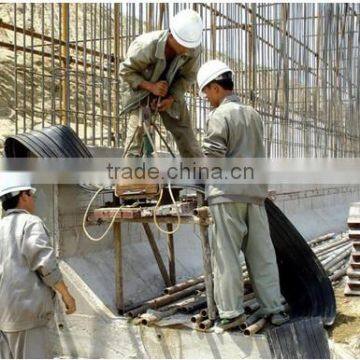

The installation of the installation and construction as shown in figure

The installation of the installation and construction as shown in figure

Use rubber water-stop installation diagram (1)

Same rubber water-stop and standard cross rubber water-stop, seam is easy to install and link. Rubber water-stop juncture place should remain vertical, as far as possible to avoid cross seams into acute Angle, so as not to cause installation, the mould and pouring concrete difficulties.

(2) rubber water-stop should be evenly placed inside the steel clamp, in the middle of the hollow in expansion joint position, by the fluctuation of the template (digging groove wood square, each a) pressure, exposed part of the bend in the rib of the template, in order to avoid damage.

(3) in rubber water-stop, rubber water-stop between steel bar and must have enough space, to ensure that the concrete is properly filled, the concrete around the rubber water-stop must fully vibrating, to ensure the concrete pore-free, not loose.

5, construction points for attention

(1) the embedded type rubber water-stop some or all of the casting during the process of concrete pouring in the concrete. Because there are many sharp corners in concrete small stones and sharp mouth bar, so when concrete is poured in and rubber water-stop positioning, attention should be paid to cast installation method and pressure, so as to avoid rubber water-stop punctured.

(2) in casting fixed, rubber water-stop migration, shall be avoided as far as the water one-way seepage path to shorten the influence and the effect of water concrete shall be fully vibrating, make the rubber water-stop and concrete is very good.

(3) joint deformation is different, the structure of rubber water-stop is different also, under the same material of rubber, rubber water-stop thickness increase with the increase of joint deformation. In order to avoid the edge of the seam rubber water-stop torn, local reinforcement structure should be adopted.

Graphic rubber water-stop joint construction method

Same rubber water-stop and standard cross rubber water-stop, seam is easy to install and link. Rubber water-stop juncture place should remain vertical, as far as possible to avoid cross seams into acute Angle, so as not to cause installation, the mould and pouring concrete difficulties.

(2) rubber water-stop should be evenly placed inside the steel clamp, in the middle of the hollow in expansion joint position, by the fluctuation of the template (digging groove wood square, each a) pressure, exposed part of the bend in the rib of the template, in order to avoid damage.

(3) in rubber water-stop, rubber water-stop between steel bar and must have enough space, to ensure that the concrete is properly filled, the concrete around the rubber water-stop must fully vibrating, to ensure the concrete pore-free, not loose.

5, construction points for attention

(1) the embedded type rubber water-stop some or all of the casting during the process of concrete pouring in the concrete. Because there are many sharp corners in concrete small stones and sharp mouth bar, so when concrete is poured in and rubber water-stop positioning, attention should be paid to cast installation method and pressure, so as to avoid rubber water-stop punctured.

(2) in casting fixed, rubber water-stop migration, shall be avoided as far as the water one-way seepage path to shorten the influence and the effect of water concrete shall be fully vibrating, make the rubber water-stop and concrete is very good.

(3) joint deformation is different, the structure of rubber water-stop is different also, under the same material of rubber, rubber water-stop thickness increase with the increase of joint deformation. In order to avoid the edge of the seam rubber water-stop torn, local reinforcement structure should be adopted.

Graphic rubber water-stop joint construction method

Figure 1: rubber water-stop section forms a site

Figure 2: first, cut the check hose connector

Figure 3: try to cut straight cut

Figure 4: the water stop 2 edge higher le cut off 3-5 cm, facilitate joint paste waterproof material

Figure 5: grinding joint clean like fill tires, but fill tires are manual, there are hand tools

Figure 6: spell joint together

Figure 7: paste with 520 glue joint

Figure 8: edging out attention to joint gap and cement

Figure 9: brush glue and then 2 sides

Figure 10: joint aperture place with waterproof tape

Figure 12: stick joint

Figure 13: attention, is two-sided

Figure 14: after surface brush glue again, again

Figure 15: both sides stick it again

Figure 16: stick with respect to ok

Contact Us

- Hongxiang New Geo-Material Co., Ltd.

- Contact nameNicky King Chat Now

- Phone086-0534-2777880

- AddressNO.2269 Dongfeng Road Decheng District, Dezhou, Shandong

Product Categories

New Products

-

Professional grass grid production factory

-

Green parking space Grass grid

-

High Strength Plastic used in the golf course Grass grid

-

Grass planting plate with the lawn grass planting brick

-

Grass planting plate with the the golf course grass mat

-

Lawn brick with the parking lot grass planting plate

-

Grass paver with fire escape

-

vertical suspension planting bag

-

outdoor vertical garden decoration planting bag

-

Vertical greening plants hang bag

-

Manufacture directly supply Slope Erosion Control coir fiber mat coconut fiber blankets

-

For mountain slope greening coir fiber mat Coir Products Coconut blanket

-

Plastic two-way stretch net used for Used for gypsum reinforced/Wall plaster reinforced

-

The landfill cover special double color HDPE liner Black and Green double color HDPE Geomambrane

-

Durable PP non woven geotextile sand bag non woven fabric sand bag

-

Hot sale app bitumen waterproofing membranes app waterproof membrane

-

Roof waterproofing membrane SBS bituminous waterproofing membrane

-

modified waterproofing membrane for roof maintenance

-

Castle villa church apartment building roof Waterproofing and insulation cheap asphalt shingles

-

SBS modified asphalt waterproofing materials for roof waterproof

-

Hot sale roof tile, cheap red roofing shingle, Fiberglass asphalt shingle manufacturer

-

Waterproof fabric bitumen waterproof Asphalt shingles

-

Asphalt shingles

-

Asphalt shingle manufacturers sales cheap asphalt shingles price asphalt roof shingles

Popular Searches

- concret water repellant

- Steel Structure Paint

- pvc water bar

- aluminum injection packers

- aluminum injection packer

- activate waterproofing

- activate waterproof

- activate waterproofs

- adaptic waterproofing

- all stones

- all stone

- water proof coating

- apply waterproofs

- be waterproofing

- be waterproof

- big waterproof

- bigs waterproofing

- building pad

- ce waterproofing

- ce waterproof

- class waterproof

- cm waterproof

- capillary crystalline waterproof material

- de waterproof

- deco waterproofing

- dome waterproofing

- e waterproof

- excell waterproofing

- gold waterproofs

- gold waterproof

Recommended Products

- HOT SALE! SBS Modified Bitumen Waterproofing Membrane – Premium Quality & Factory Direct Price!

- Asphalt Road Crack Sealant

- Factory Supply ROAD SURFACE CRACK SEALING TAPES

- factory supply road pothole quck repaid cold mix

- net crack mat for road surface crack repair in rolls

- wanji cgm high-strength non-shrinkage grouting material in stock, c60 grouting material manufacturer

- equipment foundation anchor bolt secondary grouting, high-strength, early-strength, super-fluid grouting material with 65 mpa, wanjie manufacturer

- supply equipment foundation, bridge repair and reinforcement secondary grouting, building reinforcement high-strength non-shrink grouting material

- manufacturer-supplied high-strength material non-shrink grouting material. early-strength and high-strength material for engineering reinforcement. welcome to purchase.

- External wall transparent waterproof glue

- American kitchen bathroom waterproof king

- K11 General Waterproof Coating

Find Similar Products By Category

- Construction & Decoration > Waterproof Building Materials > Asphalt Waterproof Membrane

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Hongxiang New Geo-Material Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

Nicky King

Hi there! Welcome to my shop. Let me know if you have any questions.

Nicky King

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile